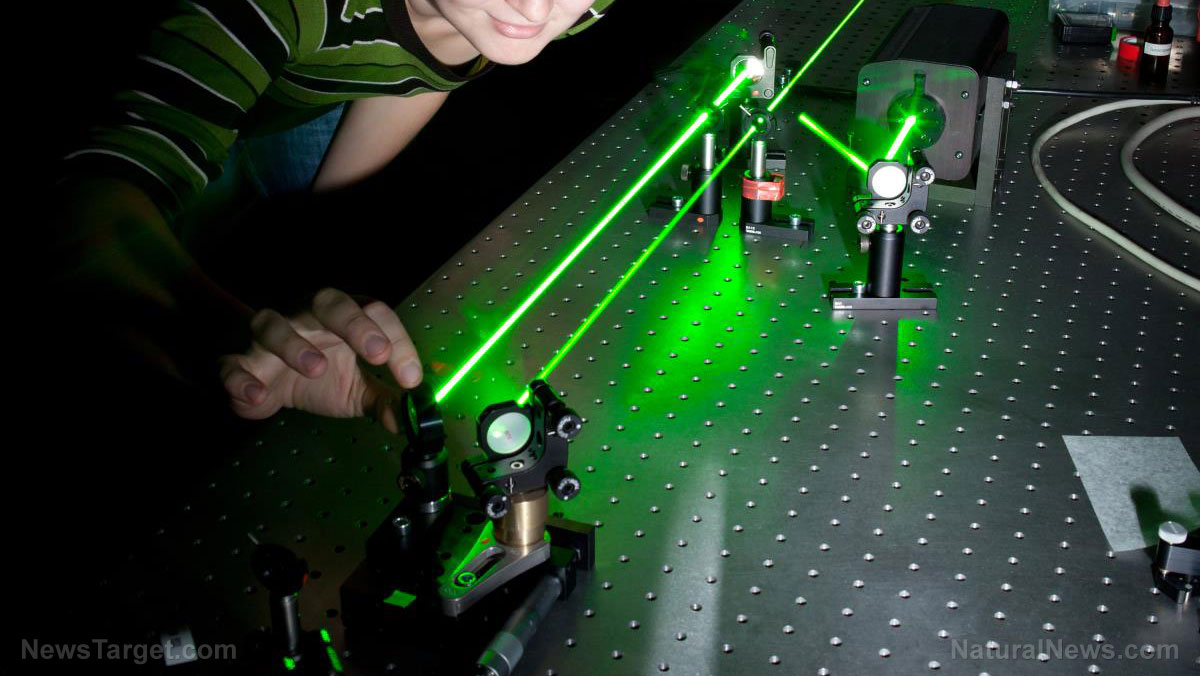

Researchers develop a technique that optimizes laser beam shaping for manufacturing or medical engineering

10/22/2019 / By Grace Olson

The quality of laser beam shaping is now better, and at no extra cost. A team of researchers from Osaka University found that using virtual diagonal phase grating can improve the accuracy of laser beam shaping and wavefront. Their findings were published in Scientific Reports.

Laser beam shaping is the redistribution of the irradiance and phase of a beam. There are many kinds of laser systems, and the beam shape and wavefront of a laser depend on which kind it is. Laser systems are used across different fields, including medicine, manufacturing, and engineering sectors. They are even used in exceedingly high energy applications, such as accelerators and nuclear fusion. Beam shape is key to ensuring that the laser is properly used for its specific purpose. (Related: New laser-based system can locate small methane leaks in an area of several square miles.)

Over the years, developers have devised ways in order to alter the shape of a laser beam. The most commonly used beam shaping methods are static and adaptive.

In the static beam shaping method, concentrated laser energy is distributed to a target field. Some systems that fall under this method are refractive beam shapers, microlens arrays, and computer-generated holograms (CGH). However, the resulting beam shape is low in edge steepness and flatness. Moreover, it results in deformed wavefronts and pulse shapes. This is because optical length inside the beam/divided beams were not considered.

On the other hand, adaptive beam shaping uses a phase grating technique, which is encoded in the spatial light simulator (SLM). It filters spatial frequency in the Fourier plane in a 4F system. In this method, the diffraction efficiency is controlled without affecting the wavefront. However, this method still limits the flatness and edge steepness of the resulting beam. While this technique has significantly developed from static beam shaping method, it can still be improved.

In this study, the researchers developed a way to address the problems on accuracy, edge steepness, and flatness. Specifically, they wanted to produce a more high-quality square flattop beam, a beam shape that is currently in demand for its versatility. This beam shape is used in varying applications, including uniform surface processing and medical engineering. However, the researchers pointed out that their technique can be applied to varying beam shapes and different kinds of lasers – from ultraviolet to those in the near-infrared domain.

The researchers called their method “virtual diagonal phase grating.”

Virtual diagonal phase grating

A key problem in the lack of accuracy, edge steepness, and flatness is the overlapping spatial-frequency distributions of extracted and residual components in the Fourier plane. Virtual diagonal phase grating addresses this problem.

First, it spatially separates the extracted and residual components in the Fourier plane. To remove the overlap, the placement of the grating vector kg is adjusted. In conventional methods, the grating vector kg is placed parallel to vectors kx and ky. In virtual diagonal phase grating, it does the opposite: the former is moved non-parallel to the two latter vectors. In this way, the resulting beam shape is in high resolution.

Best of all, the new method does not cost anything. Rather than a completely new process, the virtual diagonal phase grating method is simply a more tuned process of its predecessors.

Co-author Yoshiki Nakata said that their method “will contribute to a wide field, including basic research, manufacturing and medical engineering.”

Through optimizing the conventional processes, this virtual diagonal grating method opens new doors in industries utilizing laser systems. It overcame the limitations in edge steepness and resolution. The result, a more high-definition beam shape, is an advancement for future laser technologies.

Sources include:

Tagged Under: breakthrough, Fourier plane, future tech, innovation, inventions, laser beam, laser beam shaping, laser system, laser technology, lasers, optical technology, research, science and technology, virtual diagonal phase grating

RECENT NEWS & ARTICLES

COPYRIGHT © 2017 FUTURETECH.NEWS

All content posted on this site is protected under Free Speech. FutureTech.news is not responsible for content written by contributing authors. The information on this site is provided for educational and entertainment purposes only. It is not intended as a substitute for professional advice of any kind. FutureTech.news assumes no responsibility for the use or misuse of this material. All trademarks, registered trademarks and service marks mentioned on this site are the property of their respective owners.